Combine Heat Balance with Data Analytics to Monitor and Detect Changes in Performance

Power Plant Performance Monitoring

- Power Plant Performance

- Heat Balance Analysis

- Data-Driven Analytics

- Hybrid Thermal-Data Analytics

- Software Development

Combine Heat Balance with Data Analytics to Monitor and Detect Changes in Performance

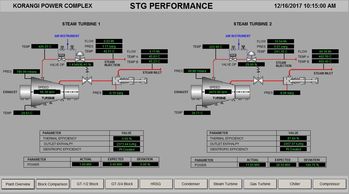

Plant measured data is continuously monitored and evaluated using a combination of first-principles, heat-balance analysis and advanced data analytics. Monitoring output can be stored in plant historian and displayed graphically for operational review.

Heat balance analysis applies conservation of mass and energy plus combustion modeling to add information to the measured data. No assumptions about performance are needed. The heat balance outputs all temperatures and flows in the system from which equipment efficiencies and heat rates are calculated.

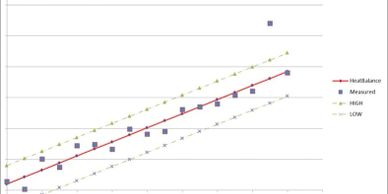

The most common problem in heat balance analysis is that plant data contains measurement and calibrations error. MapEx has the uses least-squared optimization (fitting) to detect and resolve inconsistencies in the data and produce heat balance output (red line) that is more accurate than the individual measurements (blue dots).

Performance is evaluated by comparing current performance to predicted (expected) performance. Predicted performance is from SureSense APR (Advanced Pattern Recognition) correlations. The APR correlations can be improved by using heat balance outputs as inputs to the correlations. APR predictions using only measured data (red line in the figure) are less accurate than hybrid APR correlations that use both measured and heat balance inputs.

Hybrid APR correlations use both measured data and heat balance outputs to predict expected performance. Gas turbine heat rate may be correlated as a function of air temperature, inlet pressure, air flow, compressor discharge temp and press, combustor exit temp, first stage nozzle area, compressor power, expander power and exhaust temperature. Figure shows measured and predicted heat rates for a GE 7FA gas turbine (baseload and part-load) where the predicted heat rate is from a hybrid APR.

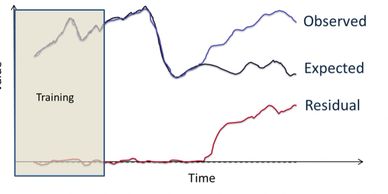

Power plant performance monitoring continuously tracks the difference between observed (measured values or calculated values from heat balance) behavior and expected behavior. Advanced pattern recognition is the most flexible and accurate technology for prediction of the expected values of performance parameters.